This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.

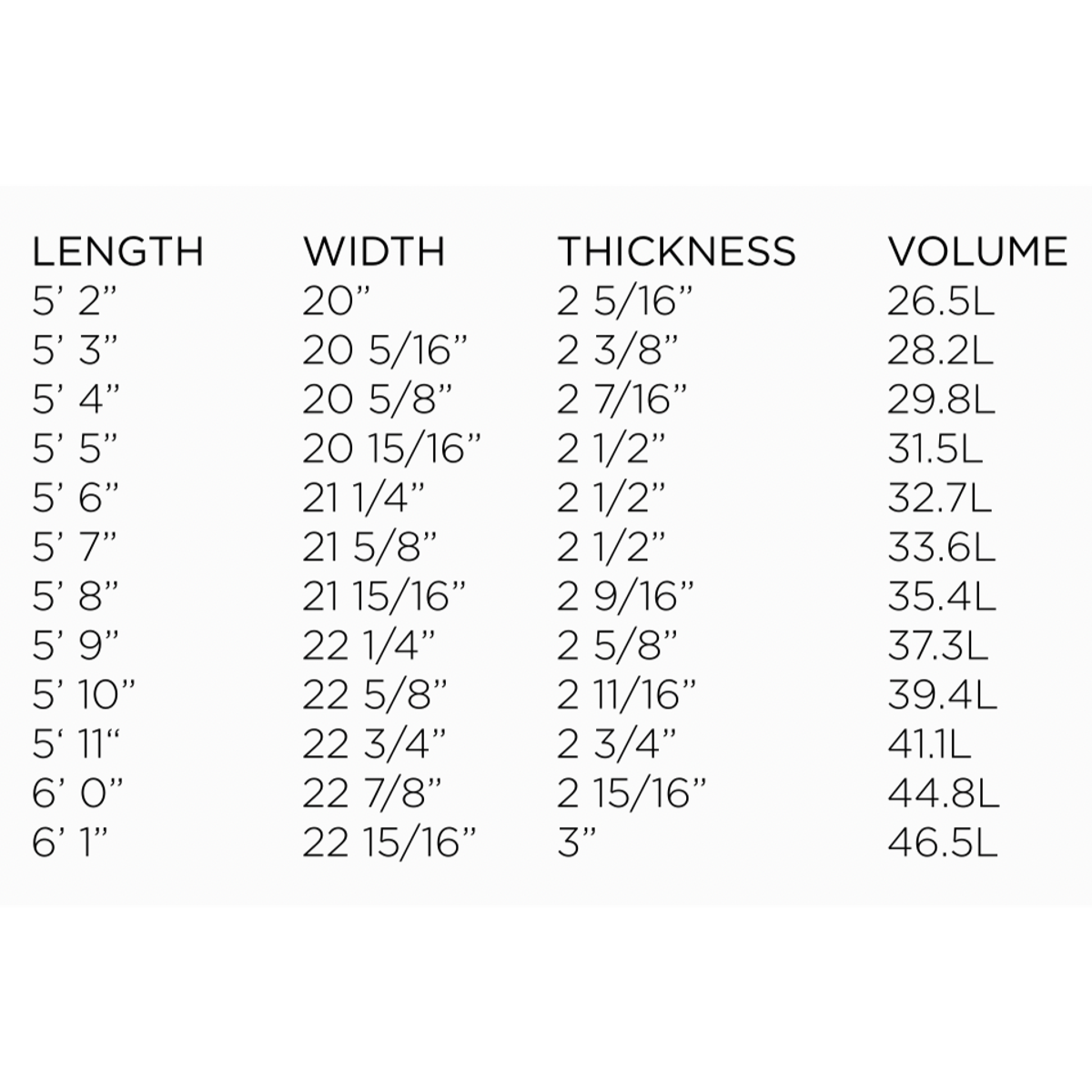

6' 0" x 22 7/8" x 2 15/16" - 44.8 L / Volcanic - Futures Fins

Ability: Beginner - Expert

Bottom Contours: Board Eat Board/Double

Rails: Full

Ideal Wave Size: 1-5f

HEY ROB, WHAT IS THE SEASIDE..?

Just evolving the Go Fish to something new, really. The Go Fish goes fast and feels skatey and loose and I love it, and riding it for a couple years made me want to feel more high performance – more carves, tighter turns. So the Seaside is about refining… less area in the tail, narrowing the tips of the swallow, creating more curve and narrowing the nose. All elements for ripping while the Go Fish stays cruisey and fun.

The Seaside is quad only, why?

I decided that if I was going to make a quad I would make a quad that’s strictly a quad … Design the concaves and bottom contours around that. I actually redesigned my entire concave setup that I’ve been using on the Moonbeam and Go Fish and did it with the quad setup in mind so that it all works together.

Why name this shape after your home break, Seaside?

Naming surfboards might be the hardest thing to do on the planet [laughing]. It’s just the perfect little stick when I surf my home spot, Seaside.

Volcanic Tech is made from Basalt Fibers Extruded from Volcanic Rocks that are crushed, melted and extruded into woven fibers that make up the cloth. The manufacture of basalt fiber requires the melting of the crushed and washed basalt rock at about 1,500 °C (2,730 °F). The molten rock is then extruded through small nozzles to produce continuous filaments of basalt fiber. Those filaments are then chopped into long stem fibers and woven into lamination cloth fiber. The cloth has similar characteristics to carbon as it relates to strength and weight however because the fibers are derived from Organic Raw materials, when combined with Bio Resins it serves as better degradable ECO alternative than using traditional carbon fiber cloth.

Basalt fiber is a relative newcomer to fiber reinforced polymers (FRPs) and structural composites. It has a similar chemical composition as glass fiber but has better strength characteristics, and unlike most glass fibers is highly resistant to alkaline, acidic and salt attack making it a good candidate for surfboard manufacturing.

Compared to carbon and aramid fiber, it has the features of wider application temperature range -452° F to 1,200° F (-269° C to +650° C), higher oxidation resistance, higher radiation resistance, higher compression strength, and higher shear strength.

The cloth can withstand high temperatures unlike carbon fiber and as a result is heavily used the Aerospace industry in the creation of rockets and and jet engines. The elasticity characteristics of this fiber is higher than that of traditional Carbon fiber allowing the board to have more flex for a natural feel under foot.

WAVE TYPE

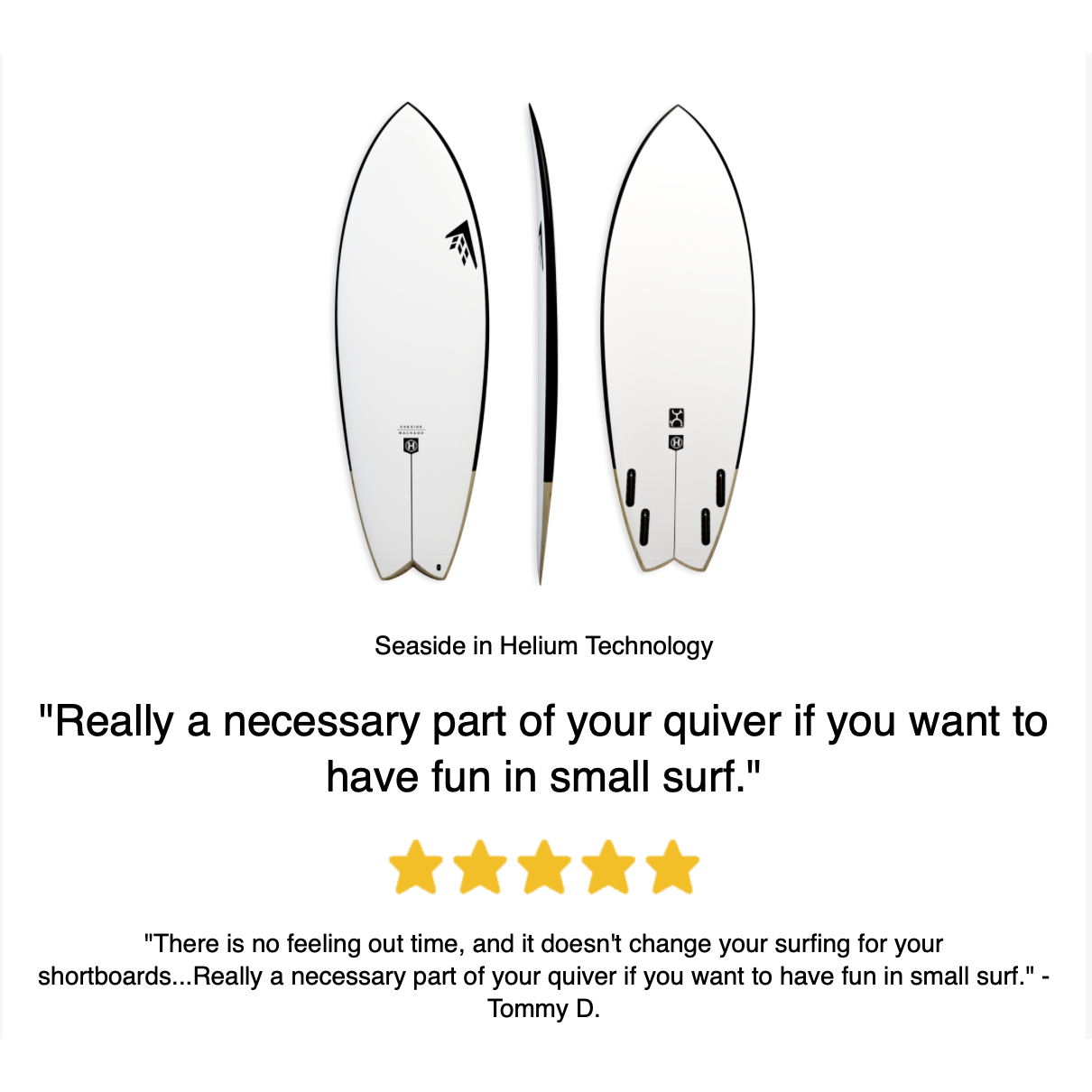

An evolution of the Go Fish, the Seaside is built to excel in small and weak waves. Think of this shape for ripping, while the Go Fish stays cruisey and fun. Recommended in 1-5’ surf, skewing towards poor/flat conditions.

BOARD FEATURES

One of our most popular outlines, this shape is inviting, fun and forgiving, with plenty of paddle power. Updated from the Go Fish, it has less area in the tail, narrowed tops of the swallow, creating more curve and a narrowed nose.